Advantages of Sea Garnet Sand for Waterjet Cutting

- Grains edges are slightly rounded

- Hard grain cores

- Clean and low dust

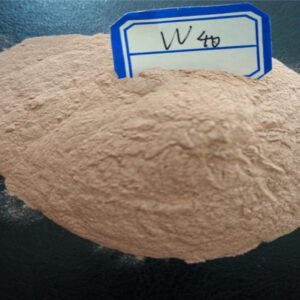

- Reddish / pink color

- High cutting precision

Recommended for: high precision cutting, most demanding materials, and Waterjet machines

Advantages of Rock Garnet Sand for Waterjet Cutting

- Dark red color

- Grain edges are super sharp

- Fast cutting speed

- Price economy

Recommended for: most Waterjet applications, including heavy-duty cutting and blasting

Chemical Composition – Typical

| Silica SiO2 | 34-40% |

| Iron(Fe2O3+FeO) | 25-31% |

| Alumina Al2O3 | 17-21% |

| Magnesium MgO | 5-6% |

| Calcium CaO | 5.0-10.0% |

| Manganese MnO | 0-1.0% |

Physical Characteristics – Typical

Specific Gravity | 3.8-4.1/cm3 |

Mohs Hardness | 7.5+ |

Acid Solubility (HCL) | <1.0% |

Bulk density | 1.8-1.9 g/cm3 |

Chloride | 10-15ppm(25ppm max) |

Colour | Red & Brown |

Melting point | 1300℃ |

Grain shape | Sub angular |

Toxic substances | none |

Conductivity | 25 ms/m |

Mineralogical Content – Typical

Almandine garnet | 97-98 % |

Quartz | ≤0.2% |

Ilmenite | ≤0.5% |

Others | ≤0.1% |

Particle Size Distribution

| MM | MESH | PERCENTAGE RETENTION |

| 1.400 | 12 | 12/24 | 20/40 | 20/60 | 30/60 | 80 |

| 0.850 | 20 | 0 | | | | |

| 0.600 | 30 | 30-40 | 0-5 | 0-5 | | |

| 0.425 | 40 | 40-50 | 50-70 | 10-25 | 0 | |

| 0.300 | 50 | 0-5 | 10-20 | 25-50 | 0-10 | 0 |

| 0.250 | 60 | | 0-10 | 25-45 | 45-60 | 30-40 |

| 0.180 | 80 | | | 0-15 | 10-25 | 40-50 |

| 0.150 | 100 | | | 0-5 | 5-20 | 0-5 |

| 0.125 | 120 | | | | 0-1 | |

Packing:1mt big bag or 25kgs PVC bags+1mt big bag