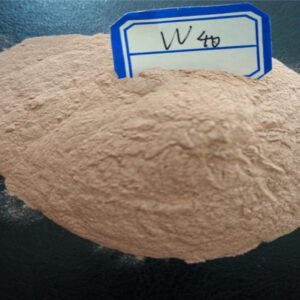

WATERJET CUTTING ABRASIVE GARNET SAND

Waterjet cutting abrasive garnet sand includes rock garnet sand 80mesh ,sea garnet sand and river garnet sand 80mesh

River garnet sand is a type of garnet abrasive that has been deposited into rivers through natural weather processes. While not better than supreme garnet abrasive, river garnet abrasive is cheaper than regular garnet abrasive because it is readily available and is easier to produce. Like sea garnet, river garnet is constantly exposed to natural elements especially flow of river water and therefore has typically smaller mesh sizes and more rounded edges. River garnet also has some impurities but depending on where it is sourced, it may have lower chloride and salt content than sea garnet.

Sea garnet sand is a garnet abrasive that has eroded from rock garnet and has been carried by natural processes into seas and oceans. Because it has been consistently exposed to pounding waves, sea garnet tends to have obtuse angles, smaller sizes and rounder shapes compared to rock garnet. Also because this garnet abrasive is extracted from seas and beaches, this abrasive has a higher chloride and salt content than regular rock garnet abrasive.The main advantage is that sea garnet sand is a natural garnet from sea beach mines. It was served directly without any crushing and milling process. Since there are no cracks in the grain, it gets less dust and of heavier specific density. For waterjet cutting work, the 80 mesh alluvial garnet sand will get a smooth cutting performance. In the meantime, it won’t block nozzles and thus save time and cost.

Rock garnet sand is a sharp and tough abrasive material in a reddish tone. It is produced as a result of crushing rocks. The mineral is chosen and processed into a product of the highest standard. It works best as a waterjet abrasive medium.It’s hardness is tied to garnet’s mineral structure and hence it gives a high durability. That’s why Premium Rock ensures a stable work of the WaterJet machine for the whole time of it’s use. Sharp edges of the grains provide high quality and smooth aftercut surface. This abrasive sand also guaranties the best cutting quality with thick materials.

Chemical Composition – Waterjet cutting abrasive garnet

| Silica SiO2 | 34-40% |

| Iron(Fe2O3+FeO) | 25-31% |

| Alumina Al2O3 | 17-21% |

| Magnesium MgO | 5-6% |

| Calcium CaO | 5.0-10.0% |

| Manganese MnO | 0-1.0% |

Physical Characteristics –Waterjet cutting abrasive garnet

| Specific Gravity | 3.8-4.1/cm3 |

| Mohs Hardness | 7.5+ |

| Acid Solubility (HCL) | <1.0% |

| Bulk density | 1.8-1.9 g/cm3 |

| Chloride | 10-15ppm(25ppm max) |

| Colour | Red & Brown |

| Melting point | 1300℃ |

| Grain shape | Sub angular |

| Toxic substances | none |

| Conductivity | 25 ms/m |

Mineralogical Content –Waterjet cutting abrasive garnet

| Almandine garnet | 97-98 % |

| Quartz | ≤0.2% |

| Ilmenite | ≤0.5% |

| Others | ≤0.1% |

Particle Size Distribution

| MM | MESH | PERCENTAGE RETENTION | ||||

| 1.400 | 12 | 12/24 | 20/40 | 20/60 | 30/60 | 80 |

| 0.850 | 20 | 0 | ||||

| 0.600 | 30 | 30-40 | 0-5 | 0-5 | ||

| 0.425 | 40 | 40-50 | 50-70 | 10-25 | 0 | |

| 0.300 | 50 | 0-5 | 10-20 | 25-50 | 0-10 | 0 |

| 0.250 | 60 | 0-10 | 25-45 | 45-60 | 30-40 | |

| 0.180 | 80 | 0-15 | 10-25 | 40-50 | ||

| 0.150 | 100 | 0-5 | 5-20 | 0-5 | ||

| 0.125 | 120 | 0-1 | ||||

Packing: 1mt big bag or 25kgs PVC bags+1mt big bag