Garnet abrasive applied fields

Garnet abrasive is a natural non-metallic abrasive, which is selected from high-quality iron aluminum garnet rock ore and processed by crushing, screening and other processes. It has the characteristics of high hardness, high density, good toughness, uniform particles, and sharp edges and corners, so it is widely used in many fields.

|  |

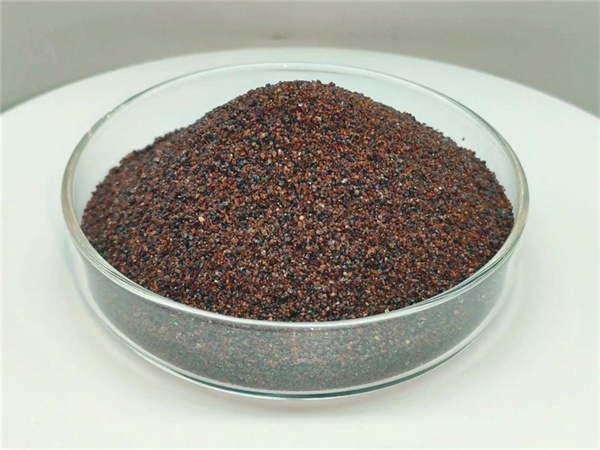

| pink garnet sand | red garnet sand |

1 Blasting field

Good sandblasting effect: Garnet sand has high hardness and uniform particle size, and can quickly cut and grind the surface of objects to achieve a certain degree of roughness and cleanliness.

Wide range of applications: Garnet sand is suitable for surface cleaning and rust removal of various metal and non-metal materials, such as steel, aluminum alloy, stainless steel, copper, galvanized parts, etc.

Long service life: Garnet sand has good toughness and is not easy to break. It can maintain sharpness for a long time even under high-speed spraying, so it has a long service life.

Environmental protection and safety: Garnet sand has a stable chemical composition, does not contain harmful substances, and does not pollute the environment. At the same time, less dust is generated during sandblasting, which has little impact on the health of workers.

2.water jet cutting industry

Garnet sand is a widely used abrasive. It is sprayed onto the surface of the workpiece along with the water flow, and uses its sharp edge combined with the water flow pressure to cut the workpiece. It is very suitable for use in marble slabs, ceramics, glass, etc.

3.construction industry

Garnet sand can also play a unique role. By utilizing its wear resistance and weathering resistance, it can be used in the construction of airport runways, wear-resistant floors, high-speed anti-slip pavements, etc.

4.Metal processing industry

Garnet abrasives can be used for grinding and polishing metal surfaces, removing burrs and oxide layers on the metal surface, and improving the finish and precision of the metal surface.

5.Metal processing industry

Garnet abrasives can be used for grinding and polishing metal surfaces, removing burrs and oxide layers on the metal surface, and improving the finish and precision of the metal surface.

6.Stone processing industry

Garnet abrasives can also be used for grinding and polishing stone to improve the smoothness and texture of the stone surface.

7.Other fields

Garnet abrasives can also be used for grinding and polishing of ceramics, plastics, rubber and other materials, showing its wide application prospects.

In short, with the continuous development and progress of industrial technology, the requirements for grinding materials are getting higher and higher. Garnet abrasives stand out among many grinding materials with their unique physical and chemical properties and become a popular choice in the market. With the continuous expansion of its application fields and the continuous growth of market demand, the market prospects of garnet abrasives are very broad.